Leveraging increased computation capability to fast-track development of machine learning solutions for medical 3D printing

As medical 3D printing enters the mainstream, an industry-wide lack of software solutions to facilitate access to the technology and ensure standardization still poses a challenge to many healthcare providers. It keeps them from taking advantage of patient care improvements and cost savings achieved by using this innovative technology.

Axial3D, a company that takes part in Digital Catapult’s Machine Intelligence Garage program, is changing the digitization of the healthcare industry with machine learning enabled solutions to prepare data for medical printing. With the development of targeted, anatomically specific computer vision algorithms to drive standardization of image segmentation (the extraction of 3D objects from 2D medical scans), Axial3D helps to improve the accuracy of 3D prints, and ultimately to increase the market adoption of medical printing. “Our vision is for every healthcare provider to have fast and easy access to expert medical 3D printing that improves surgical outcomes for patients.”

When faced with a complex case, often surgeons do not get the necessary information to confidently plan the surgical procedure from the medical images alone. A lack of surgical planning results in longer surgery times, a lack of clarity among surgical teams, higher costs to the healthcare provider, and potentially a worse outcome for the patient. The algorithms developed by Axial3D will be used to streamline the process of turning medical images into 3D printed models to guide surgical planning. With the advent of fast and easy access to 3D printing, requests for 3D prints are made directly through Axial3D’s online portal, Axial3Dinsight where the combination of automated segmentation, expert engineers and rapid 3D printing, mean Axial3D can return a patient-specific 3D printed model within 48 hours. This meets even the most time-sensitive cases as illustrated in the case below.

In the trauma unit of the Royal Victoria Hospital in Belfast, a patient presented with severe pelvis trauma following a motorcycle accident which resulted in a fracture of the acetabulum. Due to the severity of the fracture, 2D imaging did not convey the full extent of the fracture pattern. Axial3D produced a model within 24 hours, and using this, the surgical team identified small bone fragments not visible on the images, resulting in the team deciding the original plan needed to change significantly. This resulted in the surgery duration being reduced by approximately 3 hours and an improved outcome for the patient.

What is it?

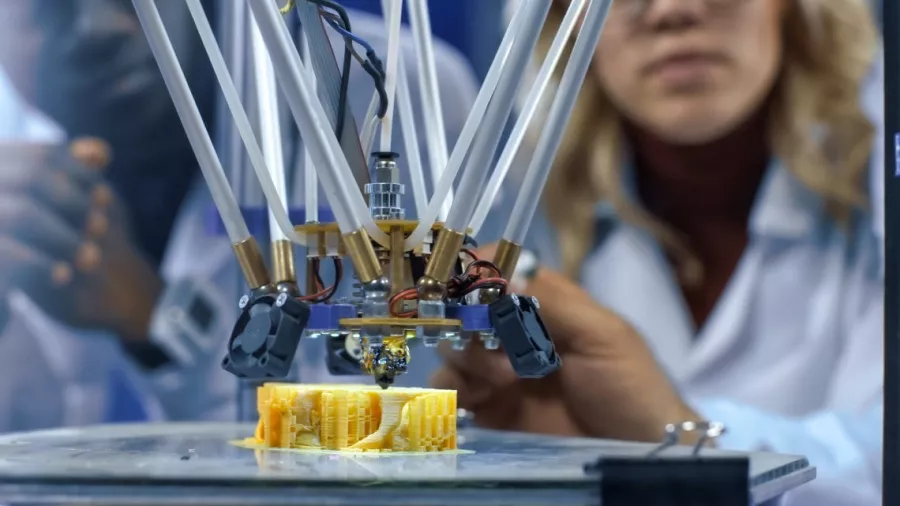

The solution developed by Axial3D spearheads an entirely new area of medical imaging segmentation. Axial3D is focused not just on the detection and extraction of specific anatomical regions from medical scans but doing it in such a way that it is then 3D-printable. Cutting edge computer vision algorithms are used to identify the relevant structure in medical images. This data is used for a fully automated 3D-reconstruction that can then be 3D printed (see figure). The training of these machine learning models requires access to large volumes of medical image data with annotations from medical visualization engineers validated by radiologists.

Axial3D also created a unique workflow platform that guides surgeons through the process of ordering 3D printed anatomical models. This ensures appropriate data governance and quality assurance processes have been put in place to produce the model, a critical requirement when producing any item that will be used in a healthcare setting.

Why Now?

Medical 3D printing is now being used by some of the world’s leading healthcare providers to improve patient care. 16 of the top 20 hospitals in the USA now have a 3D printing strategy in place. However, the process of turning these images into 3D data for 3D printing is still extremely complex, time-consuming, subjective and expensive, obstructing worldwide adoption. By automating and standardizing the process of image segmentation with machine learning, it removes human subjectivity, resulting in higher accuracy levels, as well as reproducibility and auditability not possible with manual segmentation.

Working with Machine Intelligence Garage...

Working with Machine Intelligence Garage has allowed Axial3D to accelerate the development of its software solutions. With a clearly defined market and roadmap, and a dedicated and experienced team, their biggest barrier to growth was computation power that is required for the processing of the medical imaging data. This data needs to be stored and accessible by the entire team during the development and testing process and there is a large compute footprint required due to the size of the features we are extracting. The Machine Intelligence Garage program provides Axial3D with access to on-demand cloud computing resources, in particular, the latest GPU technology. Due to the superior memory and GPU capabilities, this resource allows to rapidly iterate on their machine learning training and increase the data throughput. Machine Intelligence Garage will also allow Axial3D to experiment more freely with different training architectures and increase the size of their training features.

Like many machine learning companies in the UK Axial3D has several ex-academics working in software development, so are familiar with the raw compute power of the UK's HPC infrastructure. They also already collaborate with local universities to help drive innovation and train students through research programs. Access to cloud compute infrastructure and technical expertise from global tech companies on how to operationalize the algorithms was also very attractive – for a small company such as Axial3D access to this kind of training and mentorship is vital. It allows Axial3D to embed best practices from the very start of their development pipeline. It also allows Axial3D to move more quickly as they deploy cloud first and decrease the time for turning an idea into deployed software.

In addition to the increased compute resources which have a very practical application we are glad to be part of a national program that showcases the best of UK companies. The program also offers training on UX design and other important aspects of making machine learning products a success. It is not sufficient to have the best algorithm if users are not aware of it and using it. Therefore, the help from Machine Intelligence Garage in terms of design and marketing is also extremely important for Axial3D. We are delighted to be part of one of the first cohorts of companies in the program.

Experience 3D modeling in your own clinical practice. Trial Axial3D with a complimentary model for your next patient case.

Request a free anatomical model