The Trauma Academy by RIMASYS provides orthopedic and trauma surgeons with hands-on surgical training courses, led by world renowned instructors in a safe and practical, hyper-realistic training environment.

The Trauma Academy offers participants a unique opportunity to experience novel surgical approaches and technologies, including access to patient-specific 3D printed models provided by Axial3D.

For the Trauma Academy training courses, specific fracture causes, such as falling off a bike, are simulated at RIMASYS by machines using powerful biomechanical algorithms. CT scans taken from the fractured specimens are then sent to Axial3D, where 3D models are generated. These extreme trauma 3D models are used by the course participants to organize, define, operate and challenge their surgical plans, in addition to CT and X-ray imaging.

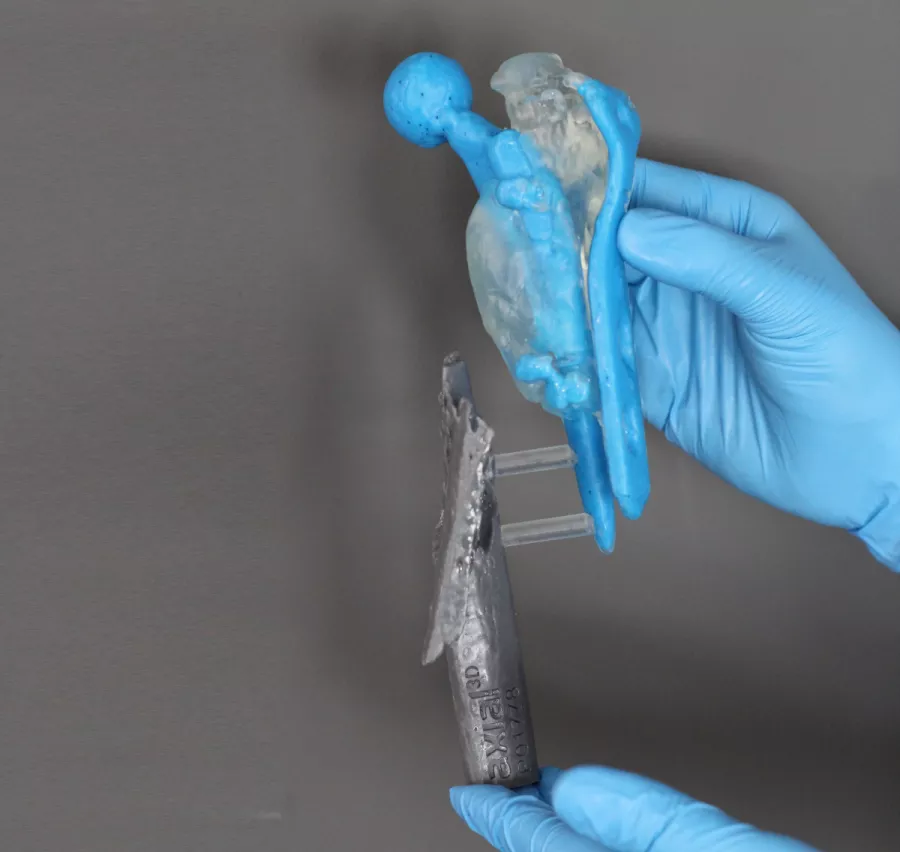

In the model above, which shows a proximal femur with an implant, you will see a massive trauma to the femur resulting in the femur being split into two very distinctive parts, with multiple smaller fragments surrounding each piece.

The segmentation of this model had additional challenges in the form of the implant, which Trauma Academy wanted to visualize in an impactful way. The segmentation of 489 CT images was more challenging than a standard model due to the excessive noise in the scan produced by the metal implant. However, Axial3D’s technology ensured the process could be done at speed and would meet Axial3D’s rigorous quality checks.

Additionally, the metal work was contrasted within the femur and the intricate fragments of the femur were connected to ensure the model was robust but also anatomically correct, before being shipped to the academy.

At the point when the 3D printed models are introduced in the courses, the participating surgeons will already have had the X-ray and CT scans for review for around 20 minutes, giving them time to begin defining which type of procedure they will carry out.

Incredibly, at the stage when the 3D printed replica of the CT scan is produced, approximately 50% of the surgeons entirely change their planned surgical approach because then they’re seeing it from a completely different angle and in some cases have seen something on the 3D model that was not clear on the conventional imagery.

Additional feedback from the surgeons participating in the courses raised a number of further benefits: the 3D models remove variability between each surgeon, support increased confidence of a good surgical outcome and aid more enhanced discussions between participants.