Summary of the Case Study published by the 3D Printing in Medicine Journal

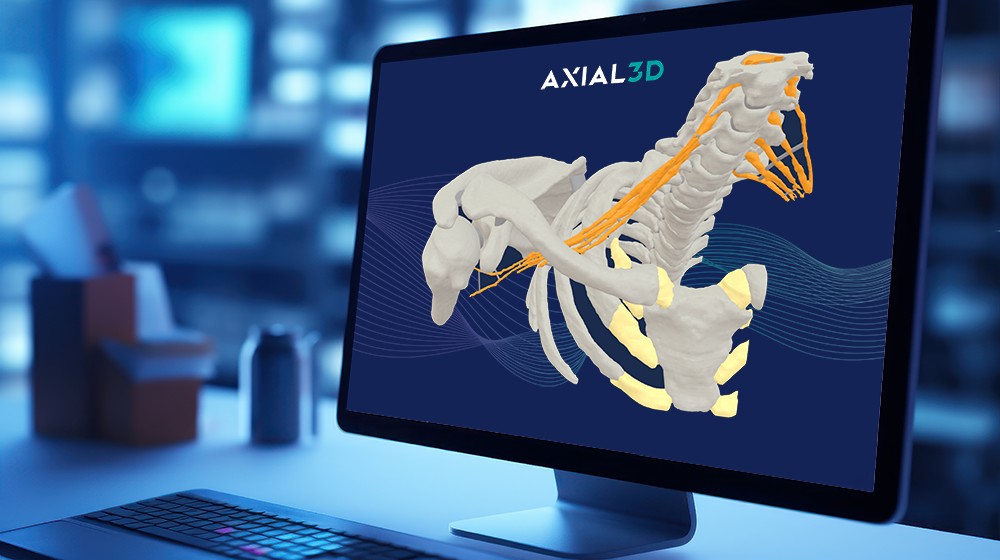

In this case study published by the 3D Printing in Medicine Journal, a multidisciplinary team from the Hospital for Special Surgery (HSS) collaborated to create a patient-specific 3D printed model of the brachial plexus and surrounding bones using MRI-only imaging, avoiding any exposure to ionizing radiation. The team used GE HealthCare’s advanced MR neurography and zero-echo time (ZTE) MRI sequences to visualize both nerve and bone structures. The imaging data was then processed by Axial3D, whose AI-powered segmentation platform automatically converted the scans into a detailed 3D model—supporting precise diagnosis, treatment planning, and patient communication.

Overview of the Study

- A 28-year-old patient, suspected of having neurologic thoracic outlet syndrome (TOS), underwent detailed MRI scanning—MR neurography for nerves and zero‑echo time (ZTE) for bones—on GE HealthCare’s 3 Tesla platform.

- Axial3D’s cloud-based INSIGHT software processed the images: automatically uploading, de‑identifying, segmenting nerves and bones, and verifying results—all within a streamlined workflow .

Key Benefits of the 3D Model

- Anatomical clarity: The full-color 3D-printed model clearly demonstrated a first-rib synostosis compressing the T1 nerve root, providing precise spatial context that was difficult to appreciate on imaging alone.

- Informed treatment planning: With the model confirming the diagnosis, the care team opted for a targeted physical therapy regimen instead of surgery—leading to significant symptom relief within weeks.

- Radiation-free precision: Using only MRI data, the model offered an accurate, detailed representation of both nerve and bone anatomy, eliminating the need for additional CT imaging or radiation exposure.

- Improved patient engagement: The tactile model made it easier for clinicians to communicate the condition and treatment plan, increasing patient understanding, trust, and adherence.

- Stronger clinical decision-making: By visualizing complex anatomy in 3D, the care team was able to plan more confidently, collaborate across specialties, and deliver a more personalized care approach.

GE HealthCare × Axial3D Collaboration

This study exemplifies the transformative benefits of our collaboration with GE HealthCare:

- Integrated MRI workflow: Utilizing GE HealthCare’s neurography and ZTE sequences, data is seamlessly fed into Axial3D’s AI-powered segmentation (Axial3D INSIGHT™) to create detailed patient-specific models

- Radiation-free modeling: Eliminates the need for additional CT scans, reducing radiation exposure and streamlining the patient experience

- Clinical advantages:

- Better visualization: Clear, tactile 3D models improve understanding of anatomy for healthcare teams and patients.

- Optimized care pathways: Enables more precise planning and enhances informed consent.

- Cost-effective delivery: Accessible through Axial3D’s platform, without major investment in on-site printing infrastructure

Why It Matters

By combining GE HealthCare’s MRI innovations with Axial3D’s automated segmentation, this collaboration proves how advanced 3D modeling:

- Enhances clinical decision-making.

- Deepens patient and team communication.

- Multi-tissue modeling (soft-tissue nerves + bone) highlights the flexibility and precision of our solution.

- Real-world clinical benefit—helped avoid surgery and accelerated recovery—reinforces the value of Axial3D models in care pathways.